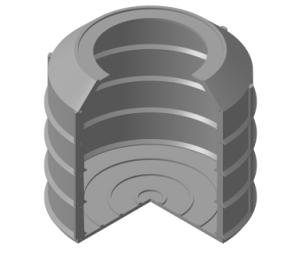

Polymer-sand rings are utilized in the construction of external engineering network wells, offering two variants with wall thicknesses of 20mm and 30mm, along with rigidity ribs up to 90mm thick. These rings are engineered to withstand soil pressure, resulting in durable and reliable well structures.

The use of uniform secondary polymer material (non-landfill) ensures the quality and tightness of the final product, as each well element maintains a consistent geometric form, guaranteeing seamless assembly without gaps or play.

Polymer wells find versatile applications, including well caissons for wells, cable ducts, irrigation systems, and septic tank installations.

For a tight and sealed well installation, it is recommended to use rings with a tongue-and-groove lock. Proper waterproofing is achieved by filling the upper groove of each well element with sealant. For cost-effective options, both bitumen-rubber mastic and polyurethane adhesive foam sealants are available.

Efficient well installation and waterproofing are our priorities, ensuring that your projects stand the test of time.